Knee Rehabilitation Device

Knee injuries account for millions of doctor visits a year. They can be debilitating and seriously impact the quality of life. Recovery can be a long, hard process. My project was to create a device that goes on your knee to make knee rehabilitation easier, safer, and more enjoyable. It has modes to track different exercises like squats and wall sits, plays music, and even has captivating LEDs. It incorporates lots of cool data science, computer science, and electrical engineering. The device is controlled by the user through a Bluetooth interface where they can give simple commands from things like setting the music or finding the angle their knee is at.

| Engineer | School | Area of Interest | Grade |

|---|---|---|---|

| Alika G | Woodside Priory | Electrical Engineering | Incoming Junior |

Final Reflection

During my time at Bluestamp, I was able to learn a lot. The specific concepts I learned that stood out to me were:

- Data Filtering (Fourier transform, Biquad filter)

- Parallel tasks (Free RTOS, Assigning tasks to cores, How stacks work)

- Audio Amp (How the components work)

- How to get + use roll, pitch, and yaw from an accelerometer (Madgwick filter)

- How C++ deals with pointers, addresses, and libraries

- Applications of optimization

Beyond that, I also gained a lot of knowledge on how to approach problems, read and write documentation, and troubleshoot. After Bluestamp, I hope to continue with engineering, using what I learned here to make my own projects (and troubleshoot them).

How the components work

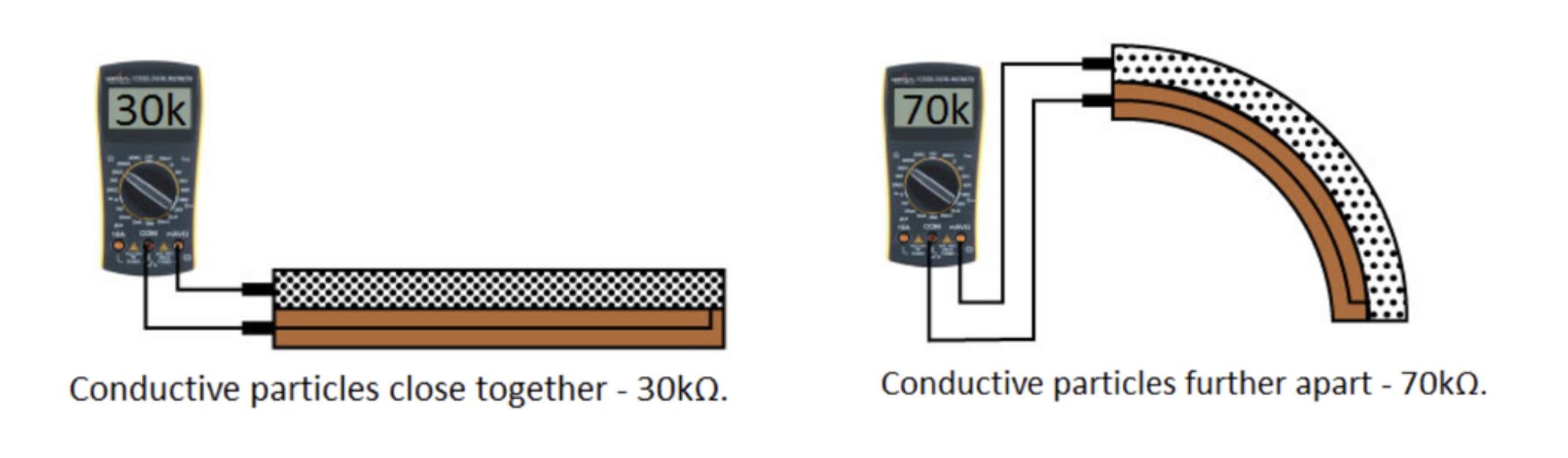

Flex Sensor:

A flex sensor is a variable resistor. When bent, the conductive particles spread apart, increasing the resistance as seen above (Figure 1). When reading in an Arduino, it is important to use analogRead rather than the conventional digitalRead used for reading most Arduino inputs. analogRead reads the voltage along a scale, unlike digitalRead, which only returns high or low. Because we want to measure all the small changes in resistance, and since resistance impacts the voltage, for a flex sensor, we need to use analogRead.

Finding a resistor for the flex sensor:

While you can use a variety of resistors for a flex sensor, some will give you a better range than others. From Ohm’s law, we know we can write Vin/Vout as \(\frac{R_{1}}{R_{1}+R_{2}}\), and in this case, the flex sensor is R2. I then measured the flex sensor’s resistance with a multimeter when it was flat and bent to get its low and high resistances. I wanted to optimise for the largest range, so I wanted to have the highest difference between the ratios of Vin/Vout at the flex sensors’ low and high resistance. This makes the equation \(\frac{x}{x+240}-\frac{x}{x+300}\) (Figure 2). Taking the derivative of that, we can find a critical point that is a maximum at \(\sqrt{240\left(300\right)}\), which is about 268.32. All the measurements are in 1k ohms, so based on these calculations, I chose a 270k ohm resistor.

Regression:

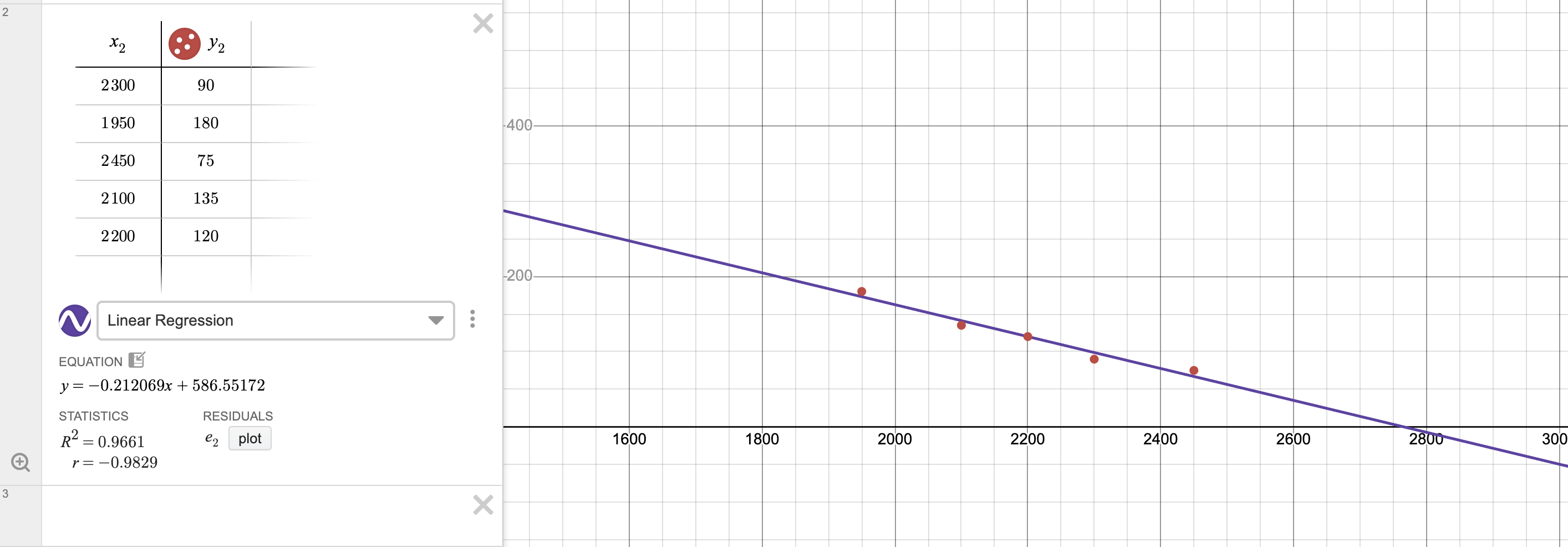

I used regression to convert the flex sensor’s raw value to degrees. After trying many types of regression, I ultimately went with a linear regression, which was pretty accurate for when the knee was 0 to 180 degrees, with less accuracy as you approach the end of that range. Regression means turning a scatter plot into an equation by finding the line of best fit. I did this on Desmos, as it lets you easily toggle between different types of regression. I wanted an R-squared value over 0.95 (R-squared is a metric to see how well the line of best fit fits the points), and I was only able to get that with linear, quadratic, or quartic regression. Quartic wasn’t very helpful since I have too few points, so while it was hitting every point, the graph was a bit wonky. Quadratic was the clear best, but because quadratic functions aren’t one-to-one, it was creating some difficulties. Linear was both accurate and what the flex sensors regression is supposed to be, between 0 and 180 degrees, according to documentation, so that’s what I ended up using (Figure 3).

Digital Biquad Filter:

In an effort to make my flex sensor data more consistent, I explored ways to create a low-pass filter. The goal of this is to push frequencies past a certain threshold to zero. The first step was recording the raw, unaveraged data from the flex sensor. I used a discrete fourier transform (see MATLAB Code for the discrete Fourier transform in Appendix A) to plot a sample of this data when my knee was at 90° for a few seconds. This data was plotted in magnitude with respect to frequency, meaning it tells you what frequencies are represented in the data and how much of each frequency is there (Figure 4).

Based on that graph, I decided the cutoff frequency should be 1 Hz. Deciding the cutoff is a tradeoff between getting rid of variability and still registering significant movements. After 1 Hz, there is a lot of noise (random spikes), and it isn’t too low that it would cut off somewhat quick movements, so that seemed like an ideal starting cutoff. I also experimented with a 0.7 Hz cutoff. I then used a computer to model what the filter looked like (Figure 5) and find the right coefficients.

A biquad filter uses 6 coefficients: b0, b1, b2, a0, a1 and a2. Figure 6 shows all the values that go into getting your output (y[n]) from your input (x[n]). In a biquad filter, you also store and use the past 2 input and output values. In the diagram, going back an iteration is represented with z-1. All the arrows in the diagram mean multiplication, and the + symbols mean addition. see Wikipedia on Digital Biquad Filters for a more indepth explanation.

Note: I took all my data and did all my filtration after the linear regression, but since it is a linear regression, you can do it either way.

Piezo Buzzers:

Piezoelectric Buzzers work by rapidly vibrating a disc of piezoelectric material at a high frequency. Piezoelectric just means it changes shape when electricity is applied to it.

Potentiometer:

Potentiometers are basically variable voltage dividers. As seen in Figure 7, potentiometers have 3 pins, with pins 1 and 3 (ground and power) connected by a resistive strip. That means the resistance between them doesn’t change. Pin 2, however, is connected to a wiper that can slide to touch any point on the resistive strip. This means the resistance between the power and pin 2 can change as the amount of the resistance strip between them changes (with more of the resistive strip meaning more resistance). The voltage that goes to pin 2 changes as the resistance changes, in an inverse relationship, just as with the flex sensor. Pin 2 is connected to an analog pin (see the flex sensor section) on the Arduino, which then measures this change, providing a value from 0 to 4095.

Vibration Motor:

I wanted to create a silent mode that still provided the user with feedback, so I decided to use a vibration motor. There are multiple types of vibration motors, but the type that I chose is the most common. It is called an Eccentric Rotating Mass (ERM) vibration motor, and as the name suggests, it vibrates by rotating a mass. The mass is uneven, so as the mass is rotated at a fast speed, the motor moves in a vibrating motion. I used a coin or pancake-style motor, so unlike larger ERMs, you can’t see the mass, but you can see Figure 8 for the structure under the cap. This type of motor is often used for haptic feedback in small devices, like it is in mine.

Speaker:

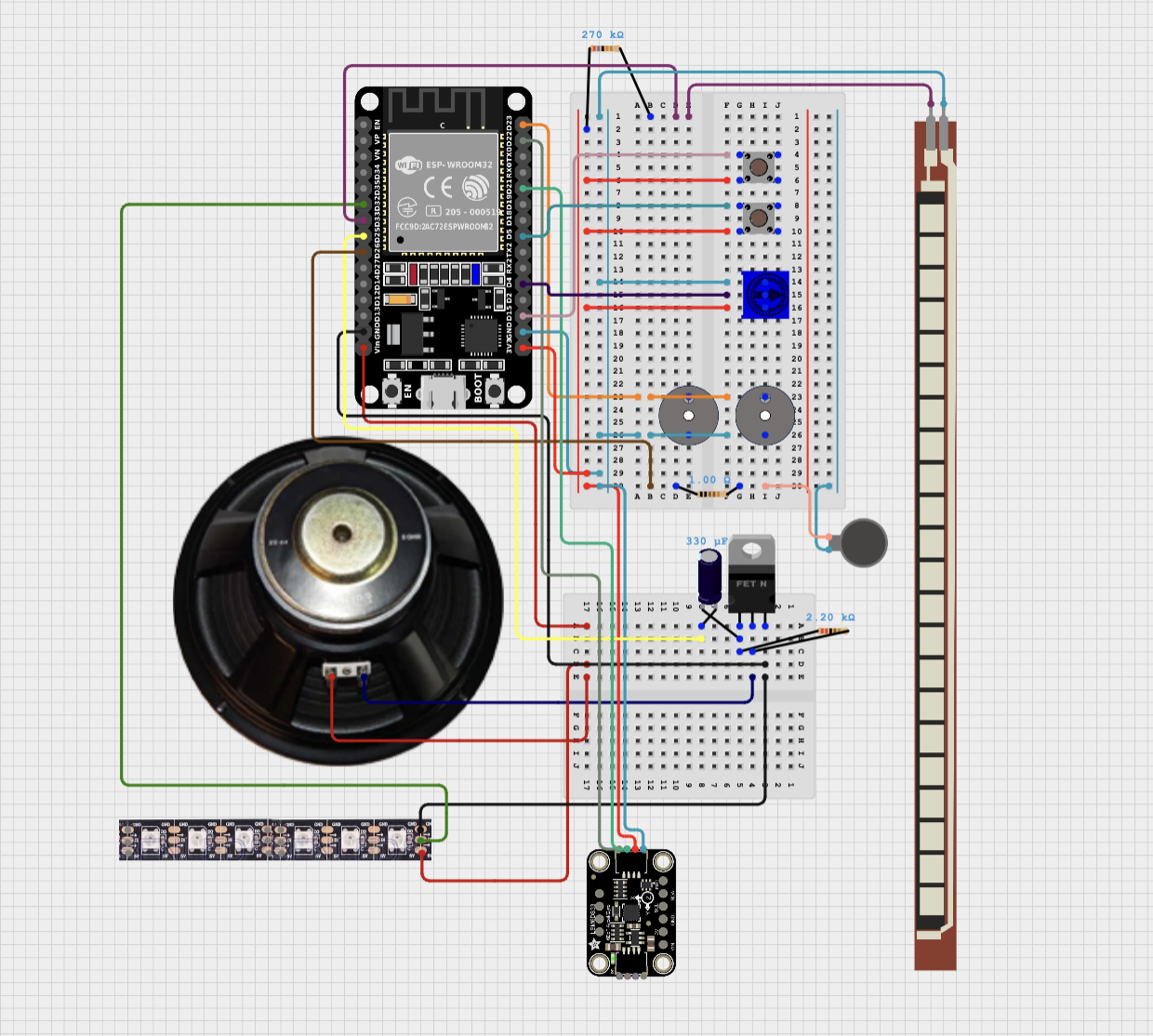

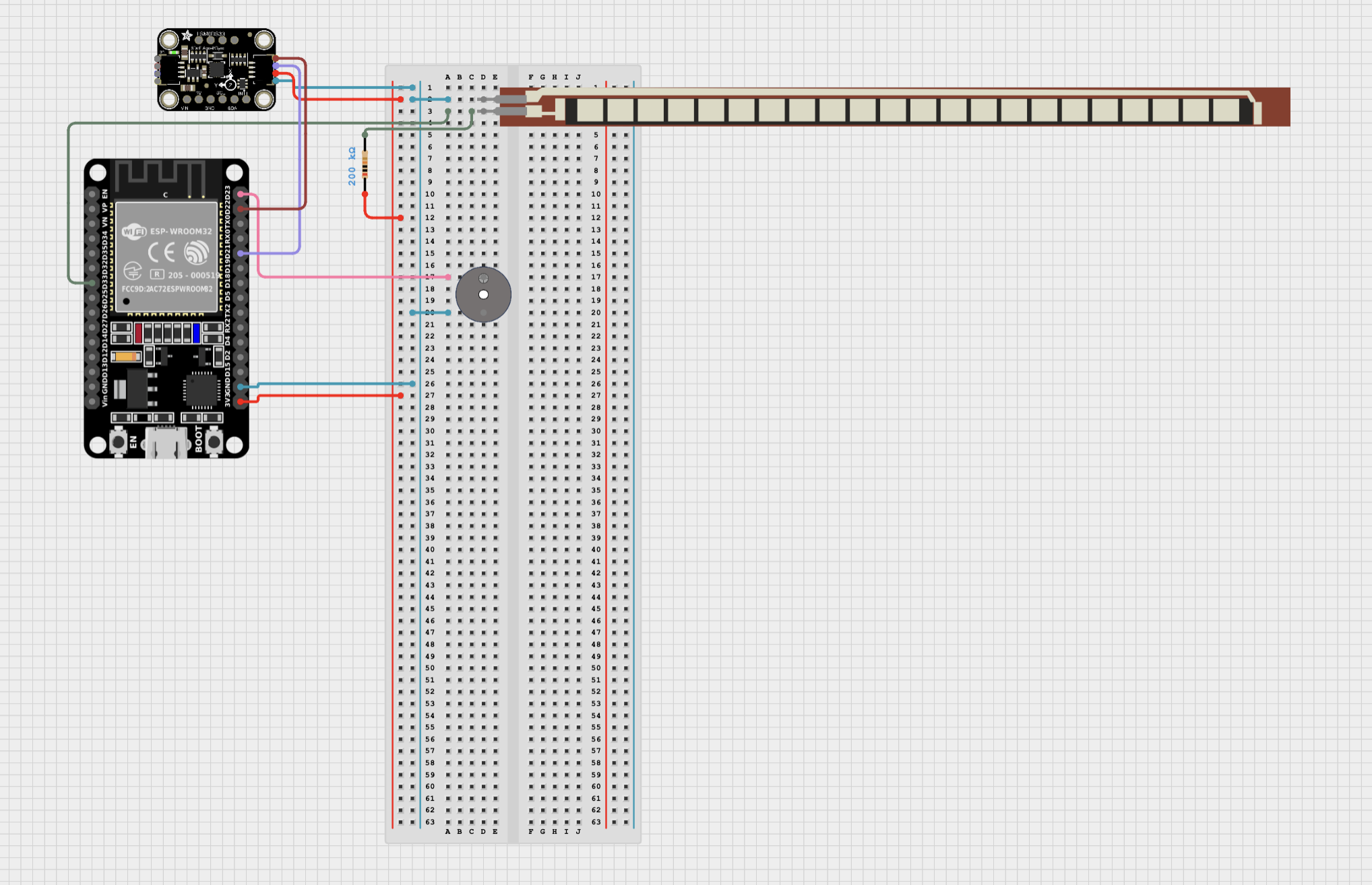

I decided to add a speaker to my project. To test this out, I made a circuit on the breadboard (Figure 9) and some test code just for it (see Speaker Test Code in Appendix A).

To wire this circuit, I needed a transistor, a capacitor, an ESP-32, in addition to the speaker. This is because the speaker needs a lot more amps than the ESP-32 can give, so we need a transistor to work as an amplifier. The resistor I used was a 2.2K ohm resistor, but you can vary the resistor depending on the desired volume (with a resistance and volume having an inverse relationship). The way this works is the ESP has the ability to make perfect sinusoidal signals, so that signal is created and passed through the capacitor to filter out the constant. The capacitor acts as a filter, and similarly to taking the derivative of a sinusoidal function, is able to preserve the shape of the signal while removing the offset. The signal then goes to the base pin of the transistor. Transistors have 3 pins: base, collector, and emitter. The base is like the gate that dictates the flow of current from the collector to the emitter. The base value is very small comparatively, as that is what is coming from the ESP’s analog pin, rather than the current going through the speaker. The 5V power goes to the speaker directly and then exits to the transistor’s collector pin. That then goes through the transistor to its emitter pin, ending at ground. There is also a feedback loop, where the base and collector pins are connected through a resistor, so the current from the collector pin is reduced by the resistor and fed back into the base pin, which “opens the gate” to a stable amount of current flow.

Running two loops concurrently:

I wanted to run two loops in true parallel (not just switching between them really fast), so my normal code could run while the speaker played music, which is called multitasking. To do this, I used FreeRTOS(free real-time operating system) in the regular Arduino IDE. More technically, multitasking means you create 2 independent tasks and then run them on the same or different cores. Lucky for me, ESP-32s have 2 cores: core 0 and core 1. My first step was figuring out what core my code was currently running on. To do this, I added Serial.println(xPortGetCoreID()); to the end of the main loop. This told me that my knee rehab code was running on core 1 (which is the default for Bluetooth, which I use). Next, I created my task as seen below:

void SpeakerLoop(void* pvParameters){

while(true){

// actual code for the task (what would be in void loop(){here} ordinarily)

}

}

The formatting for this second task is a bit different than Arduino’s default void loop(): first, the name has to be different to distinguish it from the main loop; second, you need to have the parameter void* pvParameters because it is passing in a address and FreeRTOS reguires it even if it is null; and lastly we need a while(true){} loop because otherwise the task will just finish once it reaches the end of the code. It is also important to note that while this is written like a function, if we want to use it as a task, it HAS to have void as the return type and a void* for a parameter.

Next, we want to take this SpeakerLoop function and make it a task pinned to the core not in use (in this case, core 0). The code below (placed in setup) accomplishes that.

xTaskCreatePinnedToCore (

SpeakerLoop, // Function to implement the task

"MusicTask", // Name of the task

4096, // Stack size in bytes

NULL, // Task input parameter

0, // Priority of the task

NULL, // Task handle

0 // Core where the task should run

);

The first two parameters are pretty straightforward. The stack size is how much space/memory you are giving to the task. All the variables specific to that task will be put “on top of the stack” (or actually bottom because stacks build down). The return addresses or functions, and various other things, also go on the stacks. What I did to choose the size was to start small and then just increase the size until I wasn’t getting stack overflow or stack canary errors. It is convention to use powers of 2 for the bytes (a byte is just 8 bits) that you specify. The next line is the pointer parameter we are passing in (the void* pvParameters from earlier), but since I’m not using it, I just put NULL. Priority tells the computer that if it has a conflict between two tasks, which one to choose. 0 is the highest priority. The priority doesn’t matter too much in this case because the two tasks aren’t really interacting, they are running on different cores, and neither will be that problematic if they are delayed by a very small amount of time. The task handle is the pointer (points directly to the address) or handle (an abstract reference managed by a separate system) for the task it is creating. I didn’t need one, so I just put NULL. Finally, it needs the number of the core I am pinning it to, which is 0. If you want more information on this, I recommend looking at How to Write Parallel Multitasking Applications for ESP32 using FreeRTOS & Arduino. Also, an important thing to remember is you need to add the volatile keyword before any variable accessed by multiple tasks/cores. In general, you want to have as little information as possible accessible to both, so I’m only having a boolean and a byte (instead of an int because ints are 4 bytes).

Creating your own library:

I wanted to keep my code cleaner, so when I realized I would need huge arrays of the notes and durations of each note for every song I wanted the user to be able to play, I decided to make my own music library. The way libraries work in C++ is that they are effectively just pasted in, so the code is pretty much the same. I created a file on TextEdit and then converted it from .rtf (rich text format) to .h (header). IMPORTANT: when converting your .h file will look the same, but when you actually open up the code of it, there will be random remnants from rtf trying to tell you the lost information, just delete that, otherwise it will throw errors. Then just drag the file into the folder of the project you are working in (in Documents/Arduino) next to the .ino file. In your .ino (regular code) file, include the name of your library, in my case #include "Music.h". Then you are free to code in your library, just remember that it needs to be able to compile by itself, so if you are adding functions, you might need to pass in pointers. To pass a pointer to a function, put &variableName, because, unlike Java, if you just put the name of the variable, it is not a pointer but the information (rvalues) of the object. To declare an input parameter a pointer for something, put variableType *variableName.

Note: to see the music.h library, go to the music library section in Appendix A

Neopixel Strip:

A Neopixel strip is just a bunch of Neopixels chained together. Each Neopixel has a red LED, green LED, and blue LED that shine at different brightnesses to make a rainbow of colors. Each Neopixel receives 3 bytes of information (8 bits for each color) on its data pin and gets 5V from its power pin, with its last pin being ground. These pins of each Neopixel are attached together in a Neopixel strip. You just need to connect the wires from the neopixel at the start end, with power to the ESP-32’s Vin, ground to ground, and the data pin to one of the digital pins on the ESP-32. I then tested the strip with some basic code (see Neopixel Strip Test Code in the Appendix A) before integrating it into my project.

Accelerometer:

An accelerometer works by detecting small changes caused by the movement of a small mass in response to acceleration. When under acceleration, the mass moves, but the fixed electrodes don’t (see figure 10). It uses those changes to measure acceleration.

Converting acceleration to orientation

While you can try to detect good vs. bad squats with acceleration, it’s not very consistent, as I saw when I originally tried. The problem is that acceleration is dependent on how fast you move, so while having a certain Z-axis acceleration on a slower squat would mean you had bad form, having that same acceleration on a faster squat would be fine and expected, even with perfect form. To address this, I used my accelerometer to instead describe its 3D orientation. To do this, I used Euler angles. These are measurements of rotation often used to describe the 3D orientation of an object, like the nose of a plane. As seen in Figure 11, each measures rotation along a specific axis: roll measures along the longitudinal axis, pitch along the lateral axis, and yaw along the perpendicular axis.

To convert this data, I used a Madgwick filter, which takes in the accelerometer and gyroscopes’ readings on all three axes to find the values of roll, pitch, and yaw. Arduino has a MadgwickAHRS.h library that does this. A Madgwick filter basically uses the data from the gyroscope, which measures rotational motion, to try to make a quaternion (a more complex way of noting orientation than Euler angles, but less susceptible to gimbal lock, which is when you lose a degree of freedom). The filter then uses that to predict the direction of gravity and compares those values to what the accelerometer provides, and uses that to incrementally fix the filter, in what’s called a gradient descent, which helps reduce gyroscope drift over time. The library then has functions to get the pitch, roll, and yaw from the quaternion.

Calibration

Now that I had my Euler angles, I moved to finding out how to detect a bad vs a good squat. Arduino has an in-built serial plotter, but it is very limited, so I used CoolTerm as my serial plotter. I plotted 5 variables (or traces) while a person with the compression sleeve on did good or bad squats. Based on this, I choose thresholds for the buzz variable to “beep” by switching to a value of 130. To see the code I used, look for Testing Accelerometer Calibration Code in Appendix A. I did this over a decent course of time. You can see an example of how the data looked in Figure 12.

As you can see, roll and yaw (blue and red) were not very consistent. By far the best measure of whether a squat was occurring was, expectedly, the angle of the knee (cyan). I also noticed that the pitch (green) was the best indication of a good vs. bad squat. As you can see in the figure, during a bad squat, the pitch remained roughly flat, while on a good squat, the pitch significantly rose (look at the arrow). Using the angle of the knee in conjunction with pitch, in a nested if statement, to distinguish bad and good squats worked successfully, as seen by the fact that the buzz (magenta) only went up for the bad squat.

Final Milestone

My final milestone wasn’t very technologically complex, but was honestly one of the most frustrating yet important to finish: sewing and soldering. I started with soldering. I first moved the connection from my breadboard to my first PCB, which was honestly pretty relaxing. Next, I plotted out where on the sleeve I wanted things to be. I knew I wanted the flex sensor in the back, for the best readings, and the PCB on the outer side for easy access to the buttons and potentiometer. I also wanted the LED on the top, where it would be easily visible, and the accelerometer on the upper outer thigh, as that is where you get the most change in data when squatting. Based on these restrictions, I figured out where the rest of the components needed to be placed. Next, I sewed a pouch for the battery pack, and added Velcro on it and the knee compression sleeve to make it detachable. This means you can get rid of the bulkiest item if you aren’t using it, or attach it elsewhere. It also allows the user to replace or recharge the battery pack easily, without having to worry about the whole device. I then finalized and soldered my second PCB. This PCB was much harder as it was very small and was a bad quality flex PCB, with traces that were only on one side and easily lifted off. It also didn’t have pre-made connections like the first PCB. I then moved on to sewing. I sewed all the components in through their holes (I made loops for the flex sensor, and attached the speaker to foam with two-part epoxy adhesive and then sewed the foam in).

I also had to recalibrate my flex sensor and accelerometer. My flex sensor might have needed some minor recalibration regardless, but somehow it managed to break. It was drifting a lot and maxing out values, so I ended up needing to replace it. However, the replacement was providing wildly different values, so I re-did the linear regression. The accelerometer was doing fine, but the detections of bad squat form weren’t very consistent, so I switched to using roll, pitch, and yaw (as mentioned above in the accelerometer section of How the components work).

One major challenge I was having was solder joints coming apart. While this was somewhat annoying in the start, it was a pretty easy fix originally. It also wasn’t happening much while all the components were just sitting on the table. When I ended up sewing them, that’s when many of the connections broke, and because the boards were sewn on, I had to replace them with surface mounts. The issue was that when you take the sleeve off or put it on, it stretches, and that was stressing the joints. I tried to prevent this by unplugging the connections that often came out when transferring the sleeve, but a few times I accidentally forgot or would make adjustments to the sleeve position, and some connections broke. In the end, I got so fed up that I decided to epoxy all the connections on my main PCB. That mostly fixed the problem, except for one joint, where the epoxy held the solder joint, but the joint just broke higher in the wire. After soldering that joint back together, everything held. Another challenge was that I accidentally hurt my knee during the recalibration of the accelerometer. When I fell, I accidentally damaged my ESP-32 and had to ultimately switch to a new one.

Modifications

My modifications included:

- Making a Bluetooth user interface and adjusting most things to be customizable through it

- Adding a speaker and getting it to run in parallel with my regular code

- Creating a wall sitting mode

- Adding a neopixel strip with status bar and pastel rainbow modes

- Adding assorted small components: Vibration Motor, Potentiometer, Power Button, Angle level button, Second Buzzer

Making a Bluetooth user interface and adjusting most things to be customizable through it

Rehab is a very dynamic process; it is based on your needs and abilities in the moment. I wanted to address this by letting the user choose things like at what angle a squat is complete. After that, I just kept wanting to add more customizability, like muting the buzzer, and as I started adding other components, things like switching music. I ended up with over 25 commands for the user to call through Bluetooth. The fundamental structure of the commands is: the Bluetooth sends individual decimal values of the input to the computer, then it gets converted to a string, then that string is made all lowercase and passed through an if-else ladder of all the possible commands (and a command not found error as the else). The user can type menu to see all the possible commands and their explanations (the error statement and typing hi or hello all direct you to the menu).

A challenge I encountered in this portion of the project was that at one point, the Bluetooth would randomly disconnect and not be able to print the menu or else commands. It turned out that these were two separate issues. First, the inability to print the menu was because the Bluetooth can only take a certain number of print statements in succession (~ 15) before it’s too much for it. The solution was pretty simple and just involved putting multiple lines of printing into one statement and just using \n to separate new lines. The second problem was much more confusing to solve. Ultimately, adding a continue; to the end of every if, else if, or else statement in the if-else-if ladder for Bluetooth fixed it.

Adding a speaker and getting it to run in parallel with my regular code

I decided that it would be fun to have music playing (and I wanted to learn how to make an audio amp), so I wanted to add a speaker. I first made the circuit and ran test code (see Speaker section in How the components work). As I was transferring the speaker’s music code to my main project, I realized the delays of the speaker would mess the whole project up, so I researched how to run things in parallel and ended up successfully using FreeRTOS to do this (see Running two loops concurrently section in How the components work). I then added some basic commands like play and pause music, but I still wanted to add more customizability. This would be very bulky to just add into my code, so I created a separate library for it instead (see the Creating your own library section in How the components work). I then added Bluetooth commands to do things like change songs or see what song is playing.

Creating a wall sitting mode

Wall sits were probably the most helpful exercise for my knee. I asked my PT if I could only do one exercise consistently, which one should I do, and she said wall sits. Adding a wall sit mode was pretty straightforward. Once you start the wall sit, it just stops when it detects you get up (simple for the user), and it beeps when you finish your goal. You can set your goal, start the wall sit, and get your time at any point.

Adding a neopixel strip with status bar and pastel rainbow modes

I was pretty familiar with neopixels going into this (See the Neopixel Strip section of How the components work for details). I just wanted to add neopixels for a status bar, but then I realized I can only have a status bar when the user is in counting squats or wall sitting mode, so I decided to add a looping pastel rainbow for fun in the off time. The user can turn the strip on and off, but the status bar mode is automatically engaged and disabled.

Adding assorted small components: Vibration Motor, Potentiometer, Power Button, Angle level button, Second Buzzer

These were all pretty easy to add. They are all easily accessible on the main PCB. The Potentiometer, Vibration Motor, and Buzzer have sections in How the components work. The buttons work by connecting when you push down, sending a high signal to the Arduino.

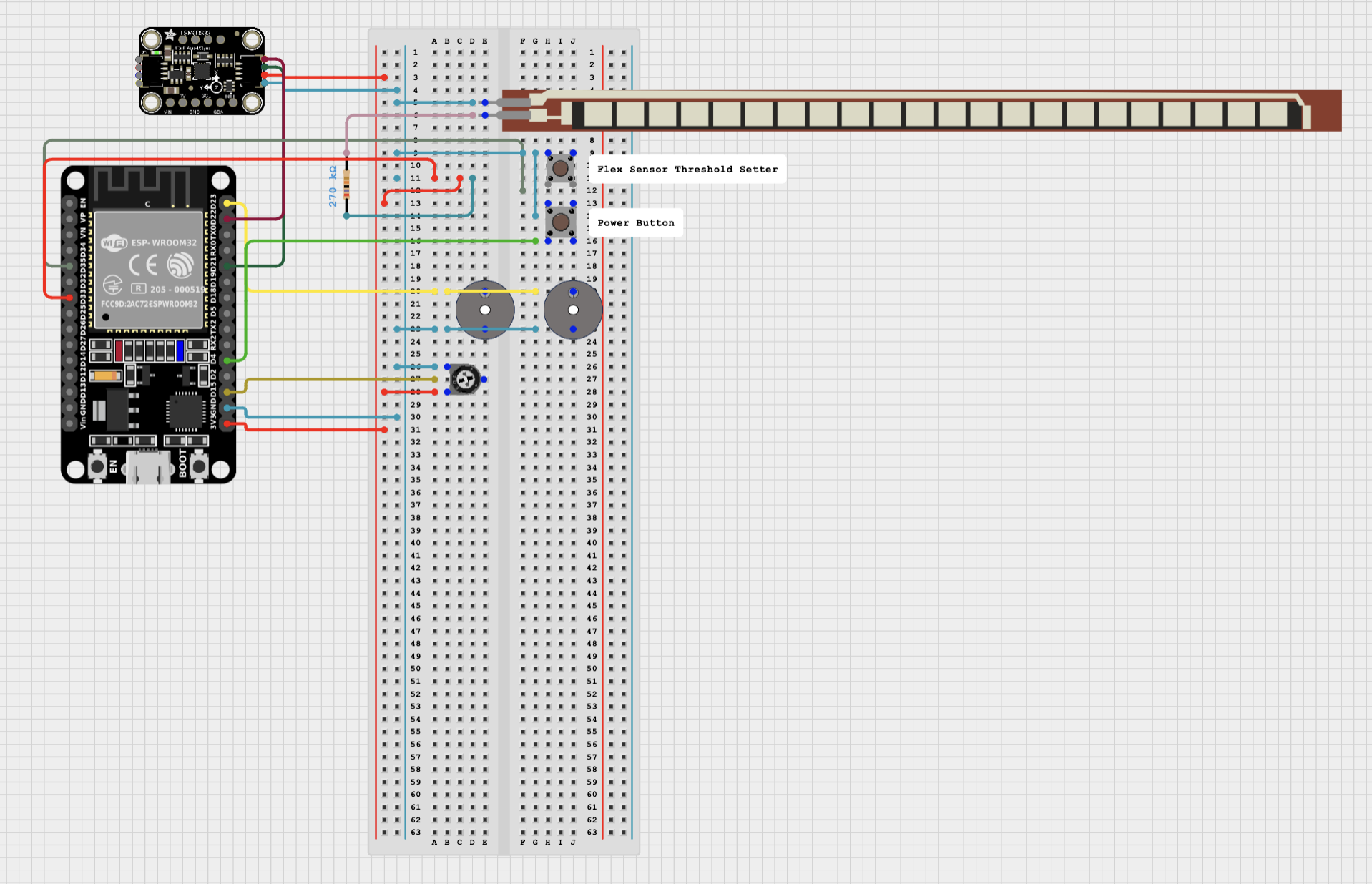

Second Milestone

My second milestone consisted of attaching the device to a knee brace (in a temporary manner) and calibrating the threshold values for the sensors based on that. I also added averaging for the sensor data so it would be more consistent and precise. You can choose how many values to average in a moving average (right now it is set at 50). I was able to attach everything with rubber bands and took some time to find the best placement for the flex sensor, which I determined to be under the knee, since it was the most accurate (see Second milestone code in Appendix A). There weren’t too many technical changes from the first milestone. I also added a button to change the threshold of the flex sensor, a power button, and a potentiometer that changes the frequency of the beeps.

I had a lot of trouble with the regression for converting the flex sensor’s raw value to degrees. I tried linear, quadratic, exponential, and logarithmic regressions. In the end I decided that the regression wouldn’t work because only the quadratic regression had a pretty high R squared value (it was ~0.99 compared to the ~0.89 of the rest) and since quadratic equations aren’t one-to-one, solving for x in terms of y gave me two seperate equations, which I couldn’t put together in a peacewise function without it failing the vertical line test. I also tried flipping the x and y values, but then none of the regressions were accurate. Ultimately, I shifted that to a system with 4 pre-set flex sensor threshold levels, where the user could choose between them with a button.

Next, I hope to get an accurate linear regression and use more advanced averaging or filtering techniques to get more consistent data. I also hope to incorporate more of a user interface-starting with buttons and later potentially having the user be able to input commands from their phones to the device. For example, for the flex sensor threshold levels, right now they are controlled with a button that just cycles through 4 preset values but hopefuly I can make it so in the bluetooth monitor the user can type in something like “Angle threshold: 75” and that would set the device to beep when the knee is at 75 degrees. Overall, my next steps are going to focus on modifications as the base part of my project is done. My 3rd milestone will be sewing and soldering everything, so I want to finish all the additional circuitry or parts my modifications might need before then.

First Milestone

My project is a knee rehabilitation device. It has two main sensors: an accelerometer and a flex sensor. An accelerometer keeps track of the static acceleration values, and the flex sensor uses variable resistance to measure the angle of bend. It uses these sensors to alert the user (with a buzzer) if their knee is bending inwards or once it passes 90 degrees.

In my first milestone, I was able to put together the flex sensor, accelerometer, buzzer, and ESP-32 Arduino with a breadboard. I was able to get data from the flex sensor and accelerometer, and code the buzzer to respond differently to both instruments crossing certain thresholds (see first milestone code in Appendix A). I was then able to connect the data to my phone through Bluetooth so I could see the real-time values even when the device is connected to a battery pack.

The main challenge that I faced in this step was getting the accelerometer to connect and send values to my computer. Originally, the accelerometer would just spit out various error codes and junk. In the end, there were a few issues with the initialization of the accelerometer object, which needed to be found in the library since there wasn’t any documentation for it.

Next, I hope to place all of this onto the knee compression sleeve and change the thresholds for the flex sensor and accelerometer so the beeping is as precise as possible. I hope to perform linear regression to get the values of the angles from the flex sensor instead of just the regular flex sensor output, which is usually in the 1000s. How I place the accelerometer will also define what the if statement for when the knee is turning inward looks like.

Appendix A: Code

First Milestone:

//adding needed libraries

#include <Wire.h>

#include <Adafruit_Sensor.h>

#include <Adafruit_LSM6DS33.h>

#include <BleSerial.h>

// creating the Accelerometer and Bluetooth object

Adafruit_LSM6DS33 lsm6ds33 {};

BleSerial ble;

// declaring and initializing variables

const int FlexPin = 33;

const int BuzzerPin = 23;

int FlexValue = 0;

void setup() {

Serial.begin(115200);

ble.begin("Alika'sKneeRehabValues");

pinMode(FlexPin, INPUT);

pinMode(BuzzerPin, OUTPUT);

//Accelerometer set up -- code from adafruit_LSM6DS33_test example from Adafruit LSM6DS library, to access examples go to file then examples and then select the right library and test

lsm6ds33.begin_I2C ();

Serial.print("Accelerometer range set to: ");

switch (lsm6ds33.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

Serial.print("Accelerometer data rate set to: ");

lsm6ds33.setAccelDataRate(LSM6DS_RATE_52_HZ);

switch (lsm6ds33.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

}

void loop() {

//get and print flex sensor data

FlexValue = analogRead(FlexPin);

Serial.print("Flex Sensor Value: ");

Serial.println(FlexValue);

ble.println("Flex Sensor Value: ");

ble.println(FlexValue);

//get and print accelerometer data

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds33.getEvent(&accel, &gyro, &temp);

Serial.print("\t\tAccel X: ");

Serial.print(accel.acceleration.x);

Serial.print(" \tY: ");

Serial.print(accel.acceleration.y);

Serial.print(" \tZ: ");

Serial.print(accel.acceleration.z);

Serial.println(" m/s^2 ");

ble.print("\t\tAccel X: ");

ble.print(accel.acceleration.x);

ble.print(" \tY: ");

ble.print(accel.acceleration.y);

ble.print(" \tZ: ");

ble.print(accel.acceleration.z);

ble.println(" m/s^2 ");

//Check and Buzz if needed

if(accel.acceleration.z < 0){

tone(BuzzerPin, 1000); // 1000 is the hertz it plays

} else if (FlexValue > 3200) { // 3200 is the raw analog value of the flex sensor at about 90°

tone(BuzzerPin, 200);

delay(200);

tone(BuzzerPin, 0);

}else{

tone(BuzzerPin, 0);

}

delay(200);

}

Second Milestone:

//adding needed libraries

#include <Wire.h>

#include <Adafruit_Sensor.h>

#include <Adafruit_LSM6DS33.h>

#include <BleSerial.h>

#include <iostream>

#include <cmath>

// creating the Accelerometer and Bluetooth object

Adafruit_LSM6DS33 lsm6ds33 {};

BleSerial ble;

// user can update variables

const int average = 50;

int AngleDangerLevel = 1; // 4 = 75, 3 = 90, 2 = 120, 1 = 135

int soundVal = 1000;

// delaring and initializing variables

int potValue = 0;

float FlexValue = 0;

float FlexThreshold;

bool on = true;

float flexvaluesarr[average];

// Where pins are

const int FlexPin = 33;

const int BuzzerPin = 23;

const int topbuttonPin = 35;

const int powerbuttonPin = 4;

const int potPin = 15;

void setup() {

Serial.begin(115200);

ble.begin("Alika'sKneeRehabValues");

pinMode(FlexPin, INPUT);

pinMode(BuzzerPin, OUTPUT);

pinMode(topbuttonPin, INPUT_PULLUP);

pinMode(powerbuttonPin, INPUT_PULLUP);

//Accelerometer set up -- code from adafruit_LSM6DS33_test example from Adafruit LSM6DS library, to access examples go to file then examples and then select the right library and test

lsm6ds33.begin_I2C ();

Serial.print("Accelerometer range set to: ");

switch (lsm6ds33.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

Serial.print("Accelerometer data rate set to: ");

lsm6ds33.setAccelDataRate(LSM6DS_RATE_52_HZ);

switch (lsm6ds33.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

// filling up the flex value averaging array so there are values that aren't 0 in all the spots

for (int i = 0; i < average; i++){

flexvaluesarr[i] = analogRead(FlexPin);

}

}

void loop() {

int PowbuttonState = digitalRead(powerbuttonPin);

while(on){

//get sensor + convert/average data

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds33.getEvent(&accel, &gyro, &temp);

float accX;

float accY;

float accZ;

FlexValue = 0;

byte topbuttonState = digitalRead(topbuttonPin);

soundVal = 1.19658*(analogRead(potPin))+100; // Converting the analog value of the potentiometer to a hertz value between 100 and 5000

accX += accel.acceleration.x;

accY += accel.acceleration.y;

accZ += accel.acceleration.z;

for (int i = 0; i < (average- 1); i++){

flexvaluesarr[i] = flexvaluesarr[i+1];

FlexValue += flexvaluesarr[i];

accX += accel.acceleration.x;

accY += accel.acceleration.y;

accZ += accel.acceleration.z;

}

flexvaluesarr[average - 1] = analogRead(FlexPin);

FlexValue += flexvaluesarr[average - 1];

FlexValue /= average;

FlexValue = -0.212069*(FlexValue)+586.55172; // linear regression

accX /= average;

accY /= average;

accZ /= average;

checkButtons();

//print flex sensor data

Serial.print("Flex Sensor Value: ");

Serial.println(FlexValue);

// ble.println("Flex Sensor Value: ");

// ble.println(FlexValue);

//print accelerometer data

Serial.print("\t\tAccel X: ");

Serial.print(accX);

Serial.print(" \tY: ");

Serial.print(accY);

Serial.print(" \tZ: ");

Serial.print(accZ);

Serial.println(" m/s^2 ");

// ble.print("\t\tAccel X: ");

// ble.print(accX);

// ble.print(" \tY: ");

// ble.print(accY);

// ble.print(" \tZ: ");

// ble.print(accZ);

// ble.println(" m/s^2 ");

//Check and Buzz if needed

if(accZ < -2.0 && accY < 1){

tone(BuzzerPin, soundVal);

} else if (FlexValue > FlexThreshold) {

tone(BuzzerPin, soundVal-20);

delay(100);

tone(BuzzerPin, 0);

}else{

tone(BuzzerPin, 0);

}

}

if (PowbuttonState == LOW) {

on = !on;

}

delay(100);

}

void checkButtons(){

// check power

if (digitalRead(powerbuttonPin) == LOW) {

on = !on;

}

// angle level

if (digitalRead(topbuttonPin) == LOW) {

if(AngleDangerLevel < 4){

AngleDangerLevel ++;

}else if (AngleDangerLevel == 4){

AngleDangerLevel = 1;

}

Serial.print("Angle Level now: ");

Serial.println(AngleDangerLevel);

ble.print("Angle Level now: ");

ble.println(AngleDangerLevel);

}

// converting angle level

switch(AngleDangerLevel){

case 1:

FlexThreshold = 135;

break;

case 2:

FlexThreshold = 120;

break;

case 3:

FlexThreshold = 90;

break;

case 4:

FlexThreshold = 75;

break;

}

delay(100);

}

Final Milestone:

//adding needed libraries

#include <Wire.h>

#include <Adafruit_Sensor.h>

#include <Adafruit_LSM6DS33.h>

#include <BleSerial.h>

#include <iostream>

#include <cmath>

#include <string>

#include <Arduino.h>

#include "DacESP32.h"

#include "pitches.h"

#include "Music.h"

#include <Adafruit_NeoPixel.h>

#include <MadgwickAHRS.h>

const int NumPixels = 20; // for neopixel strip

// Where pins are

const int FlexPin = 33;

const int BuzzerPin = 23;

const int topbuttonPin = 15;

const int powerbuttonPin = 5;

const int potPin = 4;

const int VmotorPin = 26;

const int SpeakerPin = 25;

const int NeoPin = 32;

//Variables accessed by both tasks - music commands

volatile byte songIndex = 0;

volatile bool musicPlaying = false;

// creating objects

Adafruit_LSM6DS33 lsm6ds33 {}; //accelerometer

BleSerial ble; // bluetooth

DacESP32 dac1(SpeakerPin); // speaker

Adafruit_NeoPixel strip(NumPixels, NeoPin, NEO_GRB + NEO_KHZ800); //neopixel strip

Madgwick filter; // filter

// user can update variables

const int average = 3;

const int flexAverage = 50;

int AngleDangerLevel = 1; // 4 = 75, 3 = 90, 2 = 120, 1 = 135

int soundVal = 1000;

int wallSitGoal = 60;

int squatGoal = 10;

bool printCommand = true;

bool on = true;

bool buzzerOn = true;

bool vibrationOn = true;

bool neoOn = true;

bool neoStatusMode = false;

// delaring and initializing variables

int hueOffset = 0;

int potValue = 0;

int squatCount = 0;

bool toneon = true;

bool pressed = false;

bool flexed = false;

bool countingsquats = false;

bool wallsitting = false;

bool SquatMode = true;

float wallSitTimer = 0;

float FlexValue = 0;

float FlexThreshold = 90.0;

//float b[3] = {0.20573223169460134, 0.4114644633892027, 0.20573223169460134}; // for a cutoff of 1 hz

//float a[3] = {1.0, -0.3680250041854924, 0.19095393096389768};

float b[3] = {0.13062385854433664, 0.2612477170886733, 0.13062385854433664}; // for a cutoff of 0.75 hz

float a[3] = {1.0, -0.7450366885405569, 0.2675321227179034};

float FlexIns[2] = {0,0};

float FlexOuts[2]= {0,0};

float FlexVals[flexAverage];

float roll;

float pitch;

float yaw;

float rolls[average];

float pitchs[average];

float yaws[average];

void setup(){

//general setup

Serial.begin(115200);

ble.begin("Alika'sKneeRehab");

filter.begin(20);

pinMode(FlexPin, INPUT);

pinMode(BuzzerPin, OUTPUT);

pinMode(topbuttonPin, INPUT_PULLUP);

pinMode(powerbuttonPin, INPUT_PULLUP);

pinMode(potPin, INPUT);

pinMode(VmotorPin, OUTPUT);

xTaskCreatePinnedToCore ( // making the music task and pinning it to core 0 (rest of code runs on core 1), uses FreeRTOS framework

SpeakerLoop, // Function to implement the task

"MusicTask", // Name of the task

4096, // Stack size in bytes

NULL, // Task input parameter

0, // Priority of the task

NULL, // Task handle.

0 // Core where the task should run

);

//Accelerometer set up -- code from adafruit_LSM6DS33_test example from Adafruit LSM6DS library, to access examples go to file then examples and then select the right library and test

lsm6ds33.begin_I2C ();

lsm6ds33.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

lsm6ds33.setAccelDataRate(LSM6DS_RATE_52_HZ);

lsm6ds33.setGyroDataRate(LSM6DS_RATE_52_HZ);

Serial.print("Accelerometer range set to: ");

switch (lsm6ds33.getAccelRange()) {

case LSM6DS_ACCEL_RANGE_2_G:

Serial.println("+-2G");

break;

case LSM6DS_ACCEL_RANGE_4_G:

Serial.println("+-4G");

break;

case LSM6DS_ACCEL_RANGE_8_G:

Serial.println("+-8G");

break;

case LSM6DS_ACCEL_RANGE_16_G:

Serial.println("+-16G");

break;

}

Serial.print("Accelerometer data rate set to: ");

switch (lsm6ds33.getAccelDataRate()) {

case LSM6DS_RATE_SHUTDOWN:

Serial.println("0 Hz");

break;

case LSM6DS_RATE_12_5_HZ:

Serial.println("12.5 Hz");

break;

case LSM6DS_RATE_26_HZ:

Serial.println("26 Hz");

break;

case LSM6DS_RATE_52_HZ:

Serial.println("52 Hz");

break;

case LSM6DS_RATE_104_HZ:

Serial.println("104 Hz");

break;

case LSM6DS_RATE_208_HZ:

Serial.println("208 Hz");

break;

case LSM6DS_RATE_416_HZ:

Serial.println("416 Hz");

break;

case LSM6DS_RATE_833_HZ:

Serial.println("833 Hz");

break;

case LSM6DS_RATE_1_66K_HZ:

Serial.println("1.66 KHz");

break;

case LSM6DS_RATE_3_33K_HZ:

Serial.println("3.33 KHz");

break;

case LSM6DS_RATE_6_66K_HZ:

Serial.println("6.66 KHz");

break;

}

}

void loop() {

int PowbuttonState = digitalRead(powerbuttonPin);

while(on){

// getting user input

if(ble.available() > 0){

String line = BleReadLine();

if (printCommand){

ble.println(line);

}

// responding appropriately

line.toLowerCase(); // this way it is case insesitive

if (line.equals("get my knee angle")){

ble.print("Knee angle approximately: ");

ble.print(FlexValue);

ble.println(" degrees");

ble.println();

continue;

} else if (line.equals("hello") || line.equals("hi")){

ble.println("Hello to you too, I'm excited to help you. Type Menu to see what you can do.");

ble.println();

continue;

} else if (line.equals("thanks") || line.equals("thank you")){

ble.println("Of course! always happy to help");

ble.println();

continue;

} else if (line.equals("print commands")){

ble.println("Done -- now printing commands");

printCommand = true;

ble.println();

continue;

} else if (line.equals("don't print commands")){

ble.println("Done -- no longer printing commands");

printCommand = false ;

ble.println();

continue;

} else if (line.equals("start counting squats")){

squatCount = 0;

countingsquats = true;

neoStatusMode = true;

ble.println("Ok now counting your squats");

ble.println();

continue;

} else if (line.equals("stop counting squats")){

countingsquats = false;

neoStatusMode = false;

ble.print("Ok no longer counting squats, you had ");

ble.print(squatCount);

ble.println(" reps of squats in this session");

ble.println();

continue;

} else if (line.equals("get squats reps")){

ble.print("You have done ");

ble.print(squatCount);

ble.println(" reps of squats so far");

ble.println();

continue;

} else if (line.substring(0,18).equals("set squat goal to ")){

squatGoal = line.substring(18).toInt();

ble.print("Squat goal at ");

ble.print(squatGoal);

ble.println(" squats");

ble.println();

continue;

} else if (line.equals("get flex threshold")){

ble.print("Your current flex threshold is ");

ble.println(FlexThreshold);

ble.println();

continue;

} else if (line.substring(0,22).equals("set flex threshold to ")){

FlexThreshold = line.substring(22).toFloat();

ble.print("Flex threshold now at ");

ble.print(line.substring(22));

ble.println(" degrees");

ble.println();

continue;

} else if (line.equals("start wallsit")){

tone(BuzzerPin, 0);

wallsitting = true;

neoStatusMode = true;

SquatMode = false;

ble.println("Started wallsit");

ble.println();

continue;

} else if (line.equals("how long have i been wallsiting")){

ble.print("You have been wallsetting for ");

ble.print(wallSitTimer);

ble.println(" seconds");

ble.println();

continue;

} else if (line.substring(0,21).equals("set wallsit goal to ")){

wallSitGoal = line.substring(21).toFloat();

ble.print("Wallsit goal now at ");

ble.println(line.substring(21));

ble.println();

continue;

}else if (line.equals("play music")){

musicPlaying = true;

ble.print("Music started");

ble.println();

continue;

} else if (line.equals("pause music")){

musicPlaying = false;

ble.println("Music paused");

ble.println();

continue;

} else if (line.equals("see music menu")){

printMusicMenu(&ble); //& means getting the adress

ble.println();

continue;

} else if (line.substring(0,19).equals("set music to track ")){

songIndex = (byte)line.substring(19).toInt();

ble.print("playing ");

ble.println(getSong(line.substring(19).toInt()));

ble.println();

continue;

} else if (line.equals("what is the music")){

ble.print("The music that is currently playing is ");

ble.println(getSong(songIndex));

ble.println();

continue;

} else if (line.equals("mute buzzer")){

tone(BuzzerPin, 0);

ble.print("buzzer turned off");

buzzerOn = false;

ble.println();

continue;

} else if (line.equals("unmute buzzer")){

ble.print("buzzer turned on");

buzzerOn = true;

ble.println();

continue;

} else if (line.equals("vibration off")){

ble.print("vibration turned off");

vibrationOn = false;

ble.println();

continue;

} else if (line.equals("vibration on")){

ble.print("vibration turned on");

vibrationOn = true;

ble.println();

continue;

} else if (line.equals("lights on")){

ble.print("lights strip turned on");

neoOn = true;

ble.println();

continue;

} else if (line.equals("lights off")){

ble.print("lights strip turned off");

neoOn = false;

ble.println();

continue;

} else if (line.equals("menu")){ // I had to put multiple lines in one print statment because the bluetooth gets overhemlmed if there are more than about 15 print statments

ble.println("Here is a list of the commands you can type in an what they will do (case insensitive): ");

ble.println();

ble.println("1) Print commands -- means that you can see the commands you type. \n2) Don't print commands -- means that you don't see the commands you type"); //about printing

ble.println("3) Get my knee angle -- tells you the approximate angle of your knee at that moment"); //about knee angle

ble.println("4) Set flex threshold to _YourValueHere_ -- the beeping will start when you knee reaches the angle you put in, default is 90°, you can also adjust this with the green button which cycles though set thresholds \n5) Get flex threshold -- tells you what your current get flex threshold is");

ble.println("6) Start counting squats -- starts counting the number of times you pass your flex threshold, starting at 0 \n7) Stop counting squats -- stops counting and tells you how many squats you did \n8) Get squats reps -- tells you how many squats you did \n9) set squat goal to __YourValueHere__ -- the default is 10, its just the goal that will show on your statud bar"); //about squats

ble.println("10) Set wallsit goal to _YourValueHere_ -- sets the goal (in seconds) for your wallsit, default is 60 seconds \n11) Start wallsit -- starts your wallsit (start while sitting alredy), you don't need to stop it will automatically stop when you stand up \n12) How long have I been wallsiting -- tell you how long you have been wallsiting in seconds"); // about wallsitting

ble.println("13) Play music \n14) Pause music \n15) See music menu - gives you a list songs and their artists, each corresponds to a track number \n16) set music to track _NumberOfTrackHere_ - sets the music to the song that corresponds to that track number \n17) What is the music - tells you what song is playing"); // about music

ble.println("18) mute buzzer -- buzzer is defalut on \n19) unmute buzzer \n20) vibration off -- vibration is defualt on \n21) vibration on"); //about buzzing and vibration modes

ble.println("22) lights on -- turns the neopixel strip on \n23) lights off -- turns the neopixel strip off");//about lights

ble.println();

continue;

} else {

ble.println("Sorry that is not a command I know. If you need to see available command type menu");

ble.println();

continue;

}

}

// neopixel setting

if(neoOn){

if(neoStatusMode){

if(SquatMode && countingsquats){

neopixelStatus(squatCount, squatGoal);

} else if(wallsitting){

neopixelStatus(wallSitTimer, wallSitGoal);

}

}else{

neoPixelLoopingPastelRainbow();

}

} else{

neoPixelOff();

}

//get topbutton state

byte topbuttonState = digitalRead(topbuttonPin);

// Converting the analog value of the potentiometer to a hertz value between 100 and 5000

soundVal = 1.19658*(analogRead(potPin))+100;

//accerometer

//gettting pitch yaw and roll

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds33.getEvent(&accel, &gyro, &temp);

float gx = gyro.gyro.x * 180.0 / PI;

float gy = gyro.gyro.y * 180.0 / PI;

float gz = gyro.gyro.z * 180.0 / PI;

filter.updateIMU(gx, gy, gz, accel.acceleration.x, accel.acceleration.y,accel.acceleration.z);

roll = filter.getRoll();

pitch = filter.getPitch();

yaw = filter.getYaw();

Serial.print(pitch);

Serial.print(" ");

// averaging roll pitch yaw

roll = averageVals(rolls, roll, average);

pitch = averageVals(pitchs, pitch, average);

yaw = averageVals(yaws, yaw, average);

//Filtering FlexValue

FlexValue = analogRead(FlexPin);

FlexValue = -0.192804*FlexValue + 191.33764; // linear regression

float rawFlexValue = FlexValue;

FlexValue = b[0]*FlexValue + b[1]*FlexIns[1] + b[2]*FlexIns[0] - a[1]*FlexOuts[1] -a[2]*FlexOuts[0]; // biquad filter

FlexIns[0] = FlexIns[1]; // updating varibles needed in biquad

FlexIns[1] = rawFlexValue;

FlexOuts[0] = FlexOuts[1];

FlexOuts[1] = FlexValue;

averageVals(FlexVals, FlexValue, flexAverage);

checkButtons();

//print flex sensor data

Serial.print("Flex Sensor Value: ");

Serial.println(FlexValue);

//Check and Buzz/virbate if needed - for squats

if (SquatMode){

if (FlexValue < FlexThreshold) { // beep for flex

if(toneon){

if(buzzerOn){

tone(BuzzerPin, soundVal);

} else {

tone(BuzzerPin, 0);

}

if(vibrationOn){

digitalWrite(VmotorPin, HIGH);

}

} else {

tone(BuzzerPin, 0);

digitalWrite(VmotorPin, LOW);

}

toneon = !toneon;

if(!flexed){

flexed = true;

if(countingsquats){

squatCount++;

}

}

} else if (FlexValue < 120 && pitch < -58){ // improper form

if(buzzerOn){

tone(BuzzerPin, soundVal);

} else {

tone(BuzzerPin, 0);

}

if(vibrationOn){

digitalWrite(VmotorPin, HIGH);

}

}else{

tone(BuzzerPin, 0);

if(vibrationOn){

digitalWrite(VmotorPin, LOW);

}

}

}

// wall sits mode

if(wallsitting){

if(wallSitGoal <= wallSitTimer){

if(buzzerOn){

tone(BuzzerPin, soundVal);

}

if(vibrationOn){

digitalWrite(VmotorPin, HIGH);

}

}

if(FlexValue < (FlexThreshold + 10)){ //+10 so that inconsistencies don't break the wall sit as easily

wallSitTimer += 0.1;

}else{

wallsitting = false;

SquatMode = true;

neoStatusMode = false;

float difference = wallSitGoal - wallSitTimer;

ble.print("You got up, the wall sit timer stoped at: ");

ble.print(wallSitTimer);

ble.print(" seconds. ");

if(difference > 0){

ble.print("You were about ");

ble.print(difference);

ble.println(" seconds short of your goal");

}else{

ble.println("You met your goal :) Great job!");

}

wallSitTimer = 0;

}

}

delay(50);

}

if (PowbuttonState == LOW) {

on = !on;

}

tone(BuzzerPin, 0);

digitalWrite(VmotorPin, LOW);

delay(50);

}

void checkButtons(){

// check power

if (digitalRead(powerbuttonPin) == LOW) {

on = !on;

if(on){

ble.println("on");

} else {

ble.println("off");

}

}

// angle level

if (digitalRead(topbuttonPin) == LOW && !pressed) {

pressed = true;

if(AngleDangerLevel < 4){

AngleDangerLevel ++;

}else if (AngleDangerLevel == 4){

AngleDangerLevel = 1;

}

Serial.print("Angle Level now: ");

Serial.println(AngleDangerLevel);

ble.print("Angle Level now: ");

ble.println(AngleDangerLevel);

// converting angle level

switch(AngleDangerLevel){

case 1:

FlexThreshold = 135;

break;

case 2:

FlexThreshold = 120;

break;

case 3:

FlexThreshold = 90;

break;

case 4:

FlexThreshold = 75;

break;

}

} else if (digitalRead(topbuttonPin) == LOW){

pressed = true;

} else if (digitalRead(topbuttonPin) == HIGH){

pressed = false;

}

}

//converting a line from decimal to chars

String BleReadLine(){

String str = "";

while (ble.available() > 0){

str += static_cast<char>(ble.read());

}

return str;

}

float averageVals(float* arr, float newVal, int average){ // averages values with a moving finite average

float ave = 0.0;

for (int i = 0; i < (average-1); i++){

arr[i] = arr[i+1];

ave += arr[i];

}

arr[average - 1] = newVal;

ave += arr[average - 1];

ave /= average;

return ave;

}

// neopixel options

void neoPixelLoopingPastelRainbow(){

if(neoOn){

for (int i = 0; i < NumPixels; i++) { // loops though all the neopixels

int hue = (hueOffset + i * 8) % 256; //% 256 keeps hue between 0-255 making it loop

uint32_t color = strip.ColorHSV(hue * 256, 100, 80); // 100 is saturation, 80 is brightness // this is dimming it and making it more pastel like // hue values range from 0–65535 but thats super annoying so I'm only working with 0-255, but that means I need to multiply the hue value by 256 to get it in the proper range of 0–65535

color = strip.gamma32(color); // makes the colors look more correct/smooths them

strip.setPixelColor(i, color);

}

strip.show();

hueOffset = (hueOffset + 2) % 256; // the shift

}

}

void neoPixelOff(){

for (int i = 0; i < NumPixels; i++) { // loops though all the neopixels

strip.setPixelColor(i, 0,0,0);

}

strip.show();

}

void neopixelStatus(int progress, int goal){

int compleatedPercent = ((float)progress/goal)*100;

for (int i = 0; i < NumPixels; i++) { // sets all the neopixels to red

strip.setPixelColor(i, 150,0,0);

}

for (int i = 0; 0 < compleatedPercent; i++){ // turns the ones that need to be green green and the intesity of the green of the last neopixel is based on the indivisual percent

if((int)compleatedPercent/5 > 0){

strip.setPixelColor(i, 0,150,0);

compleatedPercent -= 5;

} else {

strip.setPixelColor(i, 0, 30 * (compleatedPercent % 5),0);

compleatedPercent = 0;

}

}

strip.show();

}

// seperate task for running music

void SpeakerLoop(void* pvParameters){

while(true){

while(musicPlaying){

//setting the pointers for the music

int *melody = melodies[songIndex];

int *duration = durations[songIndex];

int currentSong = songIndex;

for (int note = 0; duration[note] != 0 && musicPlaying; note++) {

if(songIndex != currentSong){ // if song changes

break;

}

int durationTime = 1000 / duration[note];

dac1.outputCW(melody[note]); // getting note from array

delay(durationTime); // note duration

int pauseBetweenNotes = durationTime * 0.30; // pause so you can really hear the notes better

delay(pauseBetweenNotes);

dac1.outputCW(0);

}

}

float zero = 0.0;

dac1.outputVoltage(zero);

}

}

MATLAB Code for the discrete Fourier transform:

% Sampling frequency = 5Hz

Fs = 5

data = csvread('leg-sensor-data.csv');

y = fft(data);

% FFT gives two identical halves, so we take one half

L = fix(length(y)/2)+1;

% Truncate FFT data to half its original size

y = 2*y(1:L);

% Get a frequency scale for the X axis that ranges from 0 to Fs/2 Hz

Frequency = (Fs/2)*linspace(0,1,L);

plot(Frequency,20*log10(abs(y)/L))

% labeling the graph

title('Magnitude of 90° Noise')

xlabel('Frequency (Hz)')

ylabel('Magnitude (dB)')

Speaker Test Code (Hynm for the Weekend):

// add libraries

#include <Arduino.h>

#include "DacESP32.h"

#include "pitches.h"

#define SPEAKER_PIN 25 // pin for speaker (25 is an analog and digital pin)

DacESP32 dac1(25); // Creating speaker object

// song info for Coldplay's Hymn for the weekend -- Credit to HiBit <https://www.hibit.dev>

int melody[] = { // notes preset into frequencies in the pitches library

NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_G4, NOTE_F4, NOTE_F4, NOTE_F4, NOTE_F4,

NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4,NOTE_F4,NOTE_F4,

NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_G4, NOTE_F4, NOTE_F4, NOTE_F4, NOTE_F4,

NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_AS4, NOTE_C5, NOTE_AS5, NOTE_GS5, NOTE_G5, NOTE_G5,

};

int durations[] = { //notes are the types so like 4 is a quarter note

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 2, 1,

};

void setup() {

}

void loop() {

int size = sizeof(durations) / sizeof(int);

for (int note = 0; note < size; note++) {

int duration = 1000 / durations[note];

dac1.outputCW(melody[note]); // getting note from array

delay(duration); // note duration

int pauseBetweenNotes = duration * 0.30; // pause so you can really hear the notes better

delay(pauseBetweenNotes);

dac1.outputCW(0);

}

}

Neopixel Strip Test Code:

#include <Adafruit_NeoPixel.h> // Needed library

// NeoPixel info varibles

const int LEDpin = 32;

const int NumPixels = 25;

Adafruit_NeoPixel strip(NumPixels, LEDpin, NEO_GRB + NEO_KHZ800); // sets up neopixel strip object

void setup() {

strip.begin(); // initializes strip

strip.show(); // makes it show as blank

}

void loop() {

colorWipe(strip.Color(0, 70, 92), 50); // blue-ish

colorWipe(strip.Color(3, 66, 0), 50); // green

}

void colorWipe(uint32_t color, int wait) { // makes the strip turn color with a delay of wait milliseconds between when each light switches

for (int i = 0; i < strip.numPixels(); i++) {

strip.setPixelColor(i, color);

strip.show();

delay(wait);

}

}

Testing Accelerometer Calibration Code:

// importing libraries

#include <MadgwickAHRS.h>

#include <Adafruit_Sensor.h>

#include <Adafruit_LSM6DS33.h>

// making objects

Adafruit_LSM6DS33 lsm6ds33;

Madgwick filter;

// declaring varibles

const int average = 3;

const int FlexPin = 33;

int buzz = -30;

float roll;

float pitch;

float yaw;

float rolls[average];

float pitchs[average];

float yaws[average];

// flex value stuff

float FlexValue;

float b[3] = {0.13062385854433664, 0.2612477170886733, 0.13062385854433664};

float a[3] = {1.0, -0.7450366885405569, 0.2675321227179034};

float FlexIns[2] = {0,0};

float FlexOuts[2]= {0,0};

void setup() {

// general setup

pinMode(FlexPin, INPUT);

filter.begin(20); // in Hz -- make sure it matches how much your loop is running

Serial.begin(115200);

// accelerometer setup

lsm6ds33.begin_I2C ();

lsm6ds33.setAccelRange(LSM6DS_ACCEL_RANGE_2_G);

lsm6ds33.setAccelDataRate(LSM6DS_RATE_52_HZ);

lsm6ds33.setGyroDataRate(LSM6DS_RATE_52_HZ);

}

void loop() {

// getting the data

sensors_event_t accel;

sensors_event_t gyro;

sensors_event_t temp;

lsm6ds33.getEvent(&accel, &gyro, &temp);

// converting from radians to degrees

float gx = gyro.gyro.x * 180.0 / PI;

float gy = gyro.gyro.y * 180.0 / PI;

float gz = gyro.gyro.z * 180.0 / PI;

// passing in values

filter.updateIMU(gx, gy, gz, accel.acceleration.x, accel.acceleration.y,accel.acceleration.z);

// getting values

roll = filter.getRoll();

pitch = filter.getPitch();

yaw = filter.getYaw();

// averaging data

roll = averageVals(rolls, roll);

pitch = averageVals(pitchs, pitch);

yaw = averageVals(yaws, yaw);

// flex value getting and filtering

FlexValue = -0.212069*(analogRead(FlexPin))+586.55172;

float rawFlexValue = FlexValue;

FlexValue = b[0]*FlexValue + b[1]*FlexIns[1] + b[2]*FlexIns[0] - a[1]*FlexOuts[1] -a[2]*FlexOuts[0]; // biquad filter

FlexIns[0] = FlexIns[1];

FlexIns[1] = rawFlexValue;

FlexOuts[0] = FlexOuts[1];

FlexOuts[1] = FlexValue;

FlexValue = 180 - FlexValue;

// reacting

if(FlexValue < 90){

if(pitch < -58){

buzz = 130;

} else{

buzz = -30;

}

} else {

buzz = -30;

}

//printing

Serial.print(roll);

Serial.print(",");

Serial.print(pitch);

Serial.print(",");

Serial.print(yaw);

Serial.print(",");

Serial.print(FlexValue);

Serial.print(",");

Serial.println(buzz);

delay(50);

}

float averageVals(float* arr, float newVal){ // averages values with a moving finite average

float ave = 0.0;

for (int i = 0; i < (average-1); i++){

arr[i] = arr[i+1];

ave += arr[i];

}

arr[average - 1] = newVal;

ave += arr[average - 1];

ave /= average;

return ave;

}

Music Library:

#include <BleSerial.h>

#include "pitches.h"

// Credit to 2024 HiBit <https://www.hibit.dev> for the note and duration arrays

int HymnForTheWeekendNotes[] = {

NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_G4, NOTE_F4, NOTE_F4, NOTE_F4, NOTE_F4,

NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4,NOTE_F4,NOTE_F4,

NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_G4, NOTE_F4, NOTE_F4, NOTE_F4, NOTE_F4,

NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_G4,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_DS5, NOTE_D5, NOTE_DS5, NOTE_C5, REST,

NOTE_DS5, NOTE_D5, REST,

NOTE_F5, NOTE_DS5, REST,

NOTE_AS4, NOTE_C5, NOTE_AS5, NOTE_GS5, NOTE_G5, NOTE_G5

};

int HymnForTheWeekendDurations[] = { //notes are the types so like 4 is a quarter note

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4, 4, 4, 4,

4, 4, 4, 4, 4,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 4,

4, 2, 4,

4, 2, 2,

4, 4, 4, 2, 2, 1, 0

};

int EnemyNotes[] = {

NOTE_B4, REST,

NOTE_FS4, NOTE_FS4, NOTE_B4, NOTE_FS4, NOTE_E4, REST, NOTE_B3,

NOTE_D4, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_B3, NOTE_B3, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_B3, NOTE_B3,

NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_AS3, NOTE_AS3, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_AS3, NOTE_B3,

NOTE_D4, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_B3, NOTE_B3, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_D4, NOTE_B3, NOTE_B3,

NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_AS3, NOTE_AS3, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_AS3,

NOTE_B4, NOTE_A4, NOTE_G4, NOTE_D4, NOTE_FS4, NOTE_E4, NOTE_B4,

NOTE_B4, NOTE_A4, NOTE_G4, NOTE_D4, NOTE_FS4, NOTE_AS4,

REST, NOTE_E4, NOTE_FS4, NOTE_E4, NOTE_D4, NOTE_B3,

NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_B4,

REST, NOTE_E4, NOTE_FS4, NOTE_E4, NOTE_D4, NOTE_B3,

NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_B4, REST, NOTE_B3, NOTE_B3, NOTE_B3,

NOTE_D4, NOTE_CS4, NOTE_B3, NOTE_FS3, NOTE_E3, NOTE_FS3, NOTE_FS4, NOTE_B4, NOTE_FS4, NOTE_E4,

REST

};

int EnemyDurations[] = {

4, 2,

4, 8, 4, 8, 4, 2, 8,

4, 4, 8, 8, 2, 8, 4, 4, 8, 8, 2, 8,

4, 4, 8, 8, 2, 8, 4, 4, 8, 8, 2, 8,

4, 4, 8, 8, 2, 8, 4, 4, 8, 8, 2, 8,

4, 4, 8, 8, 2, 8, 4, 4, 8, 8, 2,

2, 2, 2, 4, 1, 1, 8,

2, 2, 2, 4, 1, 1,

2, 2, 8, 8, 8, 2,

8, 8, 8, 8, 8, 8, 8, 8, 8, 8, 2,

2, 2, 8, 8, 8, 2,

8, 8, 8, 8, 8, 8, 2, 2, 8, 8, 8,

2, 2, 2, 8, 4, 4, 8, 4, 8, 2,

1, 0

};

int MemoriesNotes[] = {

REST, NOTE_E5, NOTE_D5, NOTE_C5, NOTE_B4, NOTE_A4, NOTE_G4, NOTE_A4, NOTE_B4,

NOTE_G5, NOTE_E5, NOTE_F5, NOTE_G5, NOTE_E5, NOTE_F5, NOTE_G5, REST,

NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_D5, NOTE_C5,

NOTE_A4, NOTE_A4, REST, NOTE_A4, NOTE_A4, NOTE_G4, NOTE_A4, NOTE_G4, NOTE_G4, REST, NOTE_G4,

NOTE_A4, NOTE_A4, NOTE_A4, NOTE_A4, NOTE_C5, NOTE_B4,

NOTE_G5, NOTE_E5, NOTE_F5, NOTE_G5, NOTE_E5, NOTE_F5, NOTE_G5,

NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_C5, NOTE_D5, NOTE_E5, NOTE_D5, NOTE_C5,

NOTE_A4, NOTE_A4, REST, NOTE_A4, NOTE_A4, NOTE_G4, NOTE_A4, NOTE_G4, NOTE_G4, REST, NOTE_G4, NOTE_G4,

NOTE_A4, NOTE_A4, NOTE_A4, REST, NOTE_A4, NOTE_C5, NOTE_B4, NOTE_B4, NOTE_B4, NOTE_B4, NOTE_C5, REST,

REST

};

int MemoriesDurations[] = {

4, 2, 2, 2, 2, 2, 2, 2, 4,

4, 8, 8, 4, 8, 8, 2, 2,

4, 8, 8, 4, 8, 8, 4, 8, 8, 4, 8, 8,

4, 8, 8, 4, 8, 8, 8, 8, 2, 8, 8,

8, 8, 4, 4, 4, 1,

4, 8, 8, 4, 8, 8, 1,

4, 8, 8, 4, 8, 8, 4, 8, 8, 4, 8, 8,

4, 8, 8, 4, 8, 8, 8, 8, 4, 4, 8, 8,

8, 8, 8, 8, 4, 4, 8, 8, 4, 4, 8, 8,

1, 0

};

int ShapeOfYouNotes[] = {

NOTE_CS4, NOTE_E4, NOTE_CS4, NOTE_CS4, NOTE_E4,

NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_CS4, NOTE_DS4,

NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_CS4,

NOTE_B3,

NOTE_CS4, NOTE_E4, NOTE_CS4, NOTE_CS4, NOTE_E4,

NOTE_CS4, NOTE_DS4, NOTE_CS4, NOTE_E4,

NOTE_B3,

NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4,

NOTE_E4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_GS4,

NOTE_GS4, NOTE_E4, NOTE_FS4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4,

NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_GS4, NOTE_FS4,

NOTE_E4, NOTE_CS4, NOTE_CS4, NOTE_GS4, NOTE_GS4,

NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_GS4,

NOTE_GS4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_FS4, NOTE_FS4, NOTE_E4, NOTE_GS4,

NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_GS4, NOTE_FS4,

NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4, NOTE_FS4,

NOTE_E4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4,

NOTE_GS3, NOTE_B3,

NOTE_CS4, NOTE_CS4, NOTE_FS4, NOTE_GS4, NOTE_E4, NOTE_FS4,

NOTE_B3,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_CS4, NOTE_E4, NOTE_GS4,

NOTE_FS4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_FS4, NOTE_FS4,

NOTE_E4, NOTE_CS4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4,

NOTE_FS4, NOTE_E4, NOTE_CS4, NOTE_CS4,

NOTE_B3,

NOTE_CS4, NOTE_CS4, NOTE_FS4, NOTE_GS4, NOTE_E4, NOTE_FS4, NOTE_FS4,

NOTE_B3,

NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_CS4, NOTE_E4, NOTE_GS4, NOTE_FS4,

NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_FS4, NOTE_FS4, NOTE_E4,

NOTE_CS4, NOTE_B4, NOTE_GS4, NOTE_GS4, NOTE_FS4, NOTE_FS4, NOTE_E4,

NOTE_CS4, NOTE_CS4,

NOTE_GS3, NOTE_B3,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_FS4,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_E4, NOTE_FS4|

NOTE_CS4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_CS4,

NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_FS4, NOTE_E4, NOTE_FS4, NOTE_GS4,

NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_CS4,

NOTE_FS4, NOTE_GS4, NOTE_B4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4,

NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_CS4, NOTE_E4,

NOTE_FS4, NOTE_E4, NOTE_FS4, NOTE_E4, NOTE_FS4, NOTE_GS4,

NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_E4,

NOTE_FS4, NOTE_FS4, NOTE_GS4, NOTE_GS4,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_CS4,

NOTE_CS4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_FS4, NOTE_GS4,

NOTE_GS4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4,

NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_E4,

NOTE_FS4, NOTE_FS4, NOTE_GS4, NOTE_GS4,

NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4, NOTE_CS4, NOTE_CS4,

NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_CS4, NOTE_E4, NOTE_FS4, NOTE_GS4, NOTE_CS4, NOTE_E4, NOTE_FS4,

NOTE_CS4,

};

int ShapeOfYouDurations[] = {

2,2,4,2,2,4,2,2,4,2,2,2,2,2,2,2,2,4,2,2,4,2,2,2,2,8,8,4,4,8,8,8,8,8,8,8,2,8,8,4,2,8,8,4,8,8,8,4,4,8,8,8,8,8,4,8,4,8,8,8,8,4,2,8,8,8,8,4,8,8,8,8,8,8,2,8,4,8,8,8,8,8,2,4,8,8,2,4,8,8,8,8,8,8,2,8,8,4,4,4,8,8,2,4,4,2,4,2,2,4,8,8,8,2,2,8,4,8,4,4,4,4,8,8,8,8,2,8,8,4,8,8,4,2,8,4,8,4,4,4,4,2,2,2,2,4,8,8,8,2,2,2,4,8,4,4,4,4,8,8,8,8,2,8,8,4,8,8,4,2,8,8,4,8,8,4,2,2,4,2,8,8,4,8,8,4,8,8,2,8,8,4,8,8,4,8,8,2,8,8,4,4,4,8,8,2,8,8,4,8,8,8,4,8,2,4,4,8,8,4,4,8,2,8,8,4,4,4,8,8,4,8,8,8,8,8,8,4,4,4,4,8,2,8,8,4,8,8,8,4,8,4,4,4,4,4,4,4,2,8,8,4,8,8,8,4,8,4,4,4,4,4,4,4,2,8,8,4,8,8,8,4,8,4,4,4,4,4,4,4,2,8,8,4,8,8,8,4,8,4,8,8,8,8,8,8,4,4,4,4,2,0

};

int HarryPotterNotes[] = {

REST, NOTE_D4,

NOTE_G4, NOTE_AS4, NOTE_A4,

NOTE_G4, NOTE_D5,

NOTE_C5,

NOTE_A4,

NOTE_G4, NOTE_AS4, NOTE_A4,

NOTE_F4, NOTE_GS4,

NOTE_D4,

NOTE_D4,

NOTE_G4, NOTE_AS4, NOTE_A4,

NOTE_G4, NOTE_D5,

NOTE_F5, NOTE_E5,

NOTE_DS5, NOTE_B4,

NOTE_DS5, NOTE_D5, NOTE_CS5,

NOTE_CS4, NOTE_B4,

NOTE_G4,

NOTE_AS4,

NOTE_D5, NOTE_AS4,

NOTE_D5, NOTE_AS4,

NOTE_DS5, NOTE_D5,

NOTE_CS5, NOTE_A4,

NOTE_AS4, NOTE_D5, NOTE_CS5,

NOTE_CS4, NOTE_D4,

NOTE_D5,

REST, NOTE_AS4,

NOTE_D5, NOTE_AS4,

NOTE_D5, NOTE_AS4,

NOTE_F5, NOTE_E5,

NOTE_DS5, NOTE_B4,

NOTE_DS5, NOTE_D5, NOTE_CS5,

NOTE_CS4, NOTE_AS4,

NOTE_G4

};

int HarryPotterDurations[] = {

2, 4,

4, 8, 4,

2, 4,

2,

2,

4, 8, 4,

2, 4,

1,

4,

4, 8, 4,

2, 4,

2, 4,

2, 4,

4, 8, 4,

2, 4,

1,

4,

2, 4,

2, 4,

2, 4,

2, 4,

4, 8, 4,

2, 4,

1,

4, 4,

2, 4,

2, 4,

2, 4,

2, 4,

4, 8, 4,

2, 4,

1

};

int LivingOnAPrayerNotes[] = {

NOTE_B3, NOTE_D4, NOTE_E4, NOTE_E4,

NOTE_B3, NOTE_D4, NOTE_E4, NOTE_E4,

NOTE_B3, NOTE_D4, NOTE_E4, NOTE_E4,

NOTE_B3, NOTE_D4, NOTE_G4, NOTE_G4, NOTE_G4, NOTE_FS4, NOTE_E4, NOTE_D4, NOTE_E4, NOTE_E4, NOTE_D4,

NOTE_B3,

NOTE_G4, NOTE_G4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_FS4,

NOTE_G4, NOTE_FS4, NOTE_E4, NOTE_E4, NOTE_B3,

NOTE_A3, NOTE_G3,

REST

};

int LivingOnAPrayerDurations[] = {

8, 8, 8, 8,

8, 8, 8, 8,

8, 8, 8, 8,

8, 8, 8, 8, 8, 8, 8, 8, 8, 16, 16,

1,

8, 8, 8, 8, 4, 8,

4, 4, 8, 4, 4,

8, 1,

1

};

// the astrisk means it is a pointer so in this case these are pointer arrays --> unlike java names aren't automatically pointers so the * specifies it

int * melodies[] = {HymnForTheWeekendNotes, EnemyNotes, MemoriesNotes, ShapeOfYouNotes, HarryPotterNotes, LivingOnAPrayerNotes};

int * durations[] = {HymnForTheWeekendDurations, EnemyDurations, MemoriesDurations, ShapeOfYouDurations, HarryPotterDurations, LivingOnAPrayerDurations};

void printMusicMenu(BleSerial *ble){ // I just made this a seperate fuction in this library to keep it a bit cleaner - just prints the music options to BleSerial

ble->println("There are a few music options you can choose from: "); // since ble is a pointer you need -> not . becuase its basically telling it to go to the address it is pointing to on the stack and then to the fuction

ble->println("Track 0 - Hymn For The Weekend by Coldplay");

ble->println("Track 1 - Enemy by Imagine Dragons");

ble->println("Track 2 - Memories by Maroon 5");

ble->println("Track 3 - Shape of You by Ed Sheeran");

ble->println("Track 4 - Harry Potter Theme Song");

ble->println("Track 5 - Livin on a Prayer by Bon Jovi");

}

String getSong(int trackNum){ //returns the song info of a given track number

switch (trackNum){

case 0:

return "Hymn For The Weekend by Coldplay";

break;

case 1:

return "Enemy by Imagine Dragons";

break;

case 2:

return "Memories by Maroon 5";

break;

case 3:

return "Shape of You by Ed Sheeran";

break;

case 4:

return "Harry Potter Theme Song";

break;

case 5:

return "Livin on a Prayer by Bon Jovi";

break;

}

}

Bill of Materials

These are all of the main components of my project. I also used other things like wires, buttons, resistors, and more, but they are relatively small and common.

| Part | Note | Price | Link |

|---|---|---|---|

| Arduino ESP32S | Microcontroller | $13 | Link |